Components and Parts Idea/Ad Exchange, free for members. > Southwest

> CNC and computerized equiptment

> Solderless breadboard module - 1460 tie points

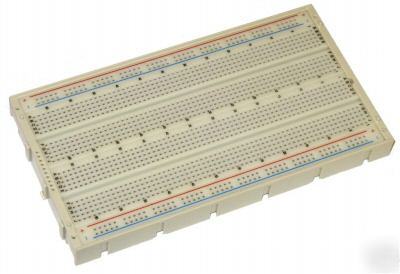

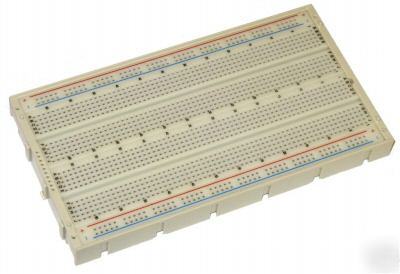

Solderless breadboard module - 1460 tie points

Solderless Breadboard Module - 1460 Tie Points

Solderless Breadboard Module - 1460 Tie Points - Package

* Expandable modular breadboard & PCB system

* Component lead bender for easier insertion

* Extra IC placement row for added flexibility

* Circuit fully tested on breadboard before soldering

* One step Circuit Transfer to QB-Series PCBs

* Direct mounting to project box (PB-128)

Solderless Breadboard Module - 1460 Tie Points

* 1x solderless breadboard in plastic tray

Forming leads to 0.1″ pitch spacing

System Expansion with Breadboard or PCB Modules

System expansion with BB & PCB modules

Combining and Interlocing Two Breadboard Modules

Combining & interlocking two BB modules

The MBB-1460 combines power bus and circuit tie-points in a style that gives a smaller footprint plus an extra row for IC positioning. This allows using shorter jumper wires for better space efficiency. Easier insertion results due to a built-in lead bender for shaping component leads quickly conforming to the 0.1″ pitch tie points on the breadboard.

The provision of side interlock latches on the holder allows expansion by simply adding other QB-PCBs or breadboard modules to form a larger system. Finally, a stable and expandable breadboard holder frees hands for faster circuit construction.

Building a working circuit on a breadboard is very time consuming; not to mention building the same again on a PCB later on. With our new and innovative direct circuit-transfer method, it enables full circuit testing on a breadboard before soldering, or transferring, to a PCB directly; thereby saving lots of time and frustrations.

In practical use, a PCB (QB-2, QB-4, QB-6, QB-8) is placed on top of a breadboard module with a solder barrier sheet in between. These PCBs have identical shapes and copper trace patterns to the tie-points on the corresponding breadboard, therefore, acting transparently in the breadboard circuit construction.

After a circuit has been built and fully tested, it is ready to be soldered on top of the PCB. With circuit power removed, progressively solder portions of the circuit on the top component side of PCB. For hard to reach leads, either space them outward or raise the component to expose the soldering points.

Re-test circuits at regular intervals so that any problems introduced in soldering can be quickly isolated. This is an efficient and confident way of transferring a working circuit built from a breadboard onto PCB. The finished PCB would then be removed for mounting to its matching holder or project box.

Visit LAB-EASY website for more great products.

Circuit Building on Breadboard via PCB

Top Side Soldering After Circuit Testing

Check our other listings for more electronic components, NPN, PNP, FET, transistors, ICs, diodes, resistors, capacitors, Microchip PICs, LEDs, and other parts for your embedded circuit.